Lights Out Manufacturing Reminders

Lights Out Manufacturing Reminders

Read Time: 3 Minutes 30 seconds

Word Count: 900

Key Takeaway: Lights-out manufacturing is a great way to change your P&L for the better.

The concept of lights-out manufacturing is simple. The idea is to run an automated process without human intervention. The idea has been around for a while. In fact, in 1785, Oliver Evans developed an automatic flour mill. This is the first completely automated industrial process that ran without human intervention.

If you think about it, that was more than 100 years before electricity became widely spread.

If you have an automated bar feeder, you may run it at night without labor. You embrace the idea of automation. Moving from an automated bar feeder to a robot is a very easy transition. That automated bar feeder is another form of CNC automation. It isn’t that different from a purpose-built, CNC machine-tending robot.

Lights-out manufacturing dramatically changes your P&L because that bottom line keeps getting fatter. How could it not?

You are running jobs with 15 minutes of labor. It takes about five minutes to enter the raw and finished parts dimensions, the material, and the piece count and to select the optimal air blowout pattern.

The software optimizes the layout pattern so you can get the greatest number of parts in the run.

Next, you place the pegs in the parts table to position the pieces in the job. Once the pegs are in place, you load the parts on the table. Those two tasks take about ten minutes.

In fifteen minutes from the task's start, you can push the green button and walk away.

That means you could start this process at 3:45 PM and still walk out the door at 4:00. You’d probably go back to your desk and get more done. But you could walk out the door and the robot would do the rest of the work.

When you returned in the morning, you’d see that the robot had been working uninterrupted.

We’ve made operating the robot so simple and easy it can be easy to forget about the CNC machine. Some simple things should always be on your checklist for running lights-out manufacturing.

- Do you have enough life left in the cutting tools to run the job to completion? Nothing is worse than having a dull cutting tool trying to get the job done when you are not around. You can hear a dull tool trying to do the job when you are there. But in lights-out manufacturing, no one is around so no one hears it.

- Use a probe to check the tool to ensure it didn’t break. This can save hours of lost production time and prevent scrap.

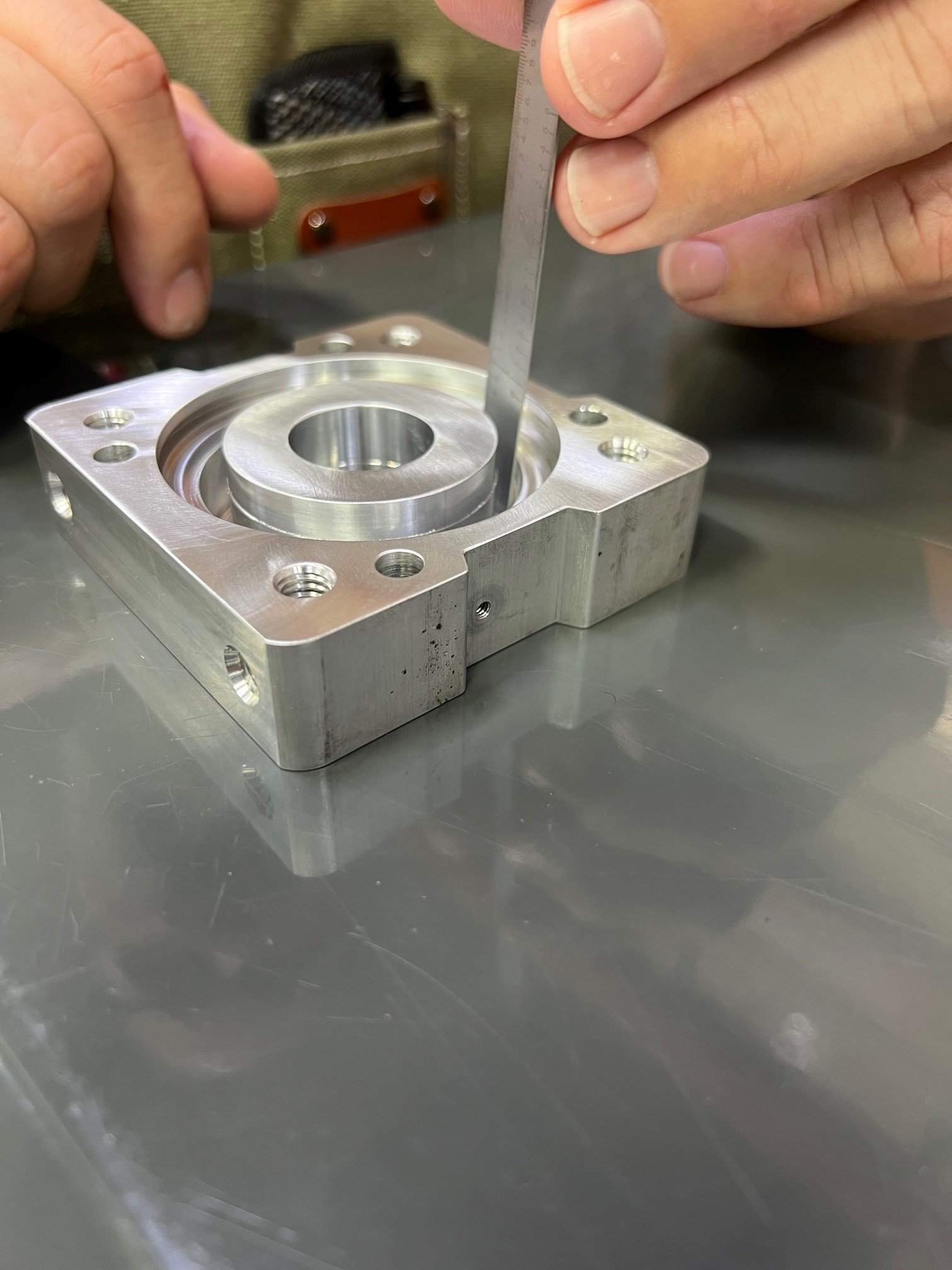

- Use a probe to check the dimensions. Validating dimensions is a critical check to ensure everything is as it should be.

- Be sure to remove excess chips before starting the job. This is especially important if you are running a long job that will create a lot of chips. You don’t want excess chips getting in the way.

- Run softer metals at night. If you have two jobs to run, one is aluminum, and the other is 4140, run the job with 4140 during the day and run the aluminum job at night. Cutting 4140 is harder on your cutting tools, and more can go wrong. It is better to have someone there during the day, so if something goes wrong, remediation can be quicker.

- Does your coolant reservoir have enough coolant to get the job done? Sometimes this gets overlooked during the day, but at least someone is there to remediate the problem. At night? It is just the mice, and they don’t say much.

Use a probe to verify measurements. It is always good to give things a second check.

What if something goes wrong?

Even when you take all the precautions, sometimes something does go wrong. Wouldn’t it be nice to know when it did?

Or, what if nothing goes wrong and you wish you had confirmation that the job went as planned and was complete?

Just like we’ve worked for a decade to optimize the software and the parts layout, we also have worked on the backend.

You can set up the robot to send you a message to let you know an intervention is required. The robot can also send you a message to let you know that the job was completed as planned

After all, communication is more important than ever. You can enter an email address and phone number and then set the conditions for the message. It is that simple.

When you start out as a machine shop, you have an advantage over those companies who offer robots but don’t have that real-life, machine shop experience. Remember, we were a machine shop before we started selling robots. We are still a machine shop even though we sell robots. Our machine shop uses robots all the time.

That is how we can be incredibly productive with three machinists and eight CNC machines. We produce substantially more now than we did before the robots with a much larger staff.

We don’t get a lot of messages from the robots. But, when we do, we always appreciate them.

And we know that the robot won’t sell our information to the auto warranty people that seem to be calling and emailing every 30 seconds!