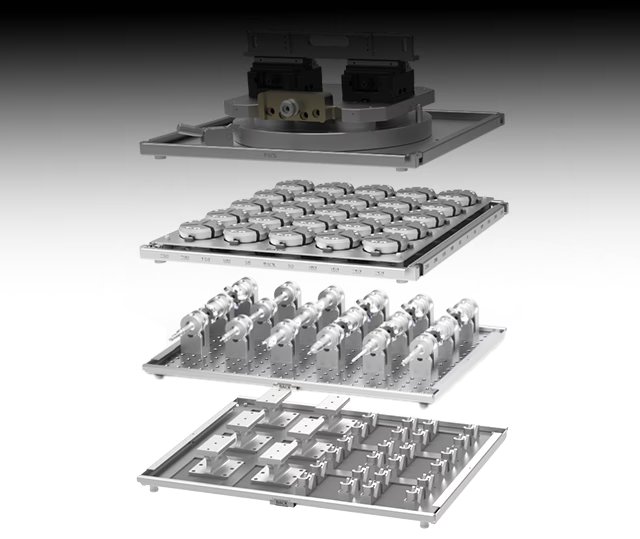

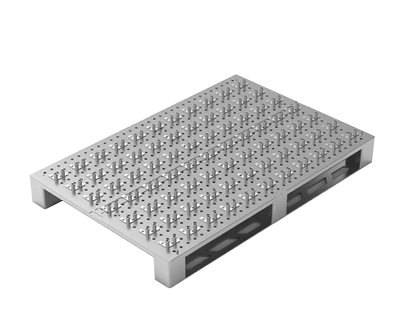

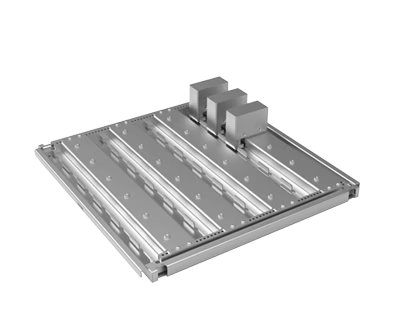

Complete your RoboJob with our modules

Modules make your automation solution fit your needs exactly. These are all building blocks to build your tailor-made solution.

We offer no less than 11 modules to perfect your RoboJob automation solution:

Would you rather see the modules in action?

Our CNC experts happily point you towards the closest module in your area.